Editorial, News, and Products

Walter Drilling Inserts Provide Extended Tool Life

The P6006 indexable inserts are said to be ideal for holemaking without a pilot drill up to 10×Dc.

Walter Turning Grades Feature Curved Wiper Cutting Edge

The FW4 and MW4 positive wiper geometries provide a wiper action that can reportedly be used to reduce machining time by using double the feed rate.

Walter Indexable Inserts Provide Improved Wear Resistance

WBH20C indexable inserts provide excellent layer bonding and long tool life due to the patent-pending method for pretreatment.

Walter Xtra-tec XT Milling Tools Feature Pocket Design

Eastec 2023: Walter’s Xtended Technology (XT) milling tools offer large cross-sections for maximum tool stability and a larger contact surface for a secure seat and reduced surface pressure.

Walter Milling Inserts Feature PCD Cutting Edges

The PCD inserts are suitable for milling a variety of nonferrous workpiece materials, such as aluminum, aluminum-silicon alloys, magnesium, magnesium-based alloys, plastics and fiber-reinforced plastics.

Selecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

Rebuilding Machine Centers: Low Cost, Higher Performance

By sending its grinding machines out for rebuilding, a tooling manufacturer achieved higher speeds at roughly three-fourths the cost of a new machine.

Walter Expands Solid-Carbide Micro Drill Product Range

The DB131 and DB133 Supreme micro pilot drill sizes are designed to minimize dimensional variations and extend tool life in steel, cast iron, nonferrous, super alloys, hard materials and other materials.

Walter Introduces New Turning Insert Geometry

The MP6 geometry combines features for medium machining, such as a positive rake angle, with those of roughing inserts.

Walter Offers New Solid-Carbide Taps for Blind-Hole Machining

Walter’s TC388 Supreme and TC389 Supreme feature patent-pending cutting geometries that fully shear off the root of the chip when reversing, thus minimizing torque peaks.

Walter Launches New Solid Carbide Drill

The DC118 Supreme solid carbide drill provides high rigidity against deflection, superior centering accuracy and four margins with corner chamfers.

Walter Extends Line of Precision Boring Tools

The new boring tools employ modular components such as cartridge holders and extensions, which are matched to the system, utilize an extensive range of indexable inserts suited for precision boring and can be used for all material groups.

Walter Introduces Coated Grade for Machining Aluminum

The WXN15 coated grade inserts can be used for copy milling, face milling, ramping, pocket milling and circular interpolation milling.

Walter Launches Axial Grooving System With Precision Cooling

The G1111-P/GX24 AF5 axial grooving system reportedly delivers maximum productivity and cutting parameters due to optimal cooling, strength and controlled chip breaking.

Walter Adds to Line of Precision Boring Tools

These new vibration-free tools provide finish machining of precise bores with high surface quality and are said to be up to three times more reliable and flexible than comparable models.

Walter Expands Line of Solid Carbide Milling Cutters, Drills

Walter’s MD173 and MD177 Supreme solid carbide milling cutters feature seven cutting edges. Additionally, the company introduces the DC165 Advance solid carbide drill for non-ferrous and cast iron applications.

Non-Contact Blue-Laser Measurement System

Laser Contour Check provides high-precision measurement of various tool parameters on cylindrical tools with diameters from 1 to 52 mm.

Walter Launches New Line of PVD-Grade Carbide Milling Inserts

This new grade is now reportedly capable of 30% greater performance in stainless steels and heat-resistant super alloys, and up to 75% greater performance in steels than comparable grades.

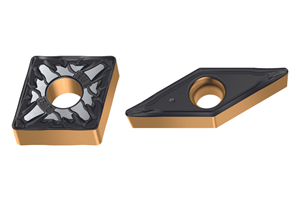

Walter Introduces New Insert Grades for Turning Steel

Walter offers three Tiger·tec Gold grades specifically designed for turning operations in steel and cast iron.

Walter Launches Profile Milling Cutter

Walter launches the Xtra-tec XT M5460, a profile milling cutter that delivers precision and tool life.

Versatile Drilling Grade for Drilling Aluminum

This grade is designed to enable reliable chip removal due to its smooth surface with a reduced tendency toward adhesion and buildup on the cutting edge, thereby increasing process reliability and wear resistance.

Walter Adds to Line of Copy Turning Systems

Walter says this copy turning system for internal machining can boost tool life, cut tooling costs and increase indexing accuracy by 50%.

Cermet Turning Insert Maximizes Dimensional Accuracy

Walter’s cermet turning insert is designed to ensure dimensional accuracy, superior surface finish and reduced vibration.

Low-Adhesion Drilling Grade Improves Durability in Aluminum

Walter drilling inserts using its WNN15 PVD drilling grade can see up to a 200% tool life increase compared to conventional drilling grades.

Walter Introduces Latest Tool-Grinding Machine

Its latest tool-grinding machine, the Helitronic G 200, is designed for grinding and re-sharpening rotationally symmetrical cutting tools.

Carbide Drill Designed to Deliver Coolant Closer to Cutting Edge

Walter’s DC 175 Supreme solid carbide drill is designed for increased performance in stainless steel and superalloy machining.

Walter Insert Designed for Interrupted Cuts, Hard Materials

The CBN-grade insert WBH30 boasts 65% CBN content, which helps offer wear resistance in hardened steel.

Improved Chip Removal With Boring Bar Line, Offset Adapter

Together with A2201's larger offset dimensions, the internal coolant delivery of the A3001 boring bar optimizes chip removal, adding to its superior surface finishes. Walter says it provides fast and productive counterboring and internal profiling of parts.

Walter's New Inserts Machine Non-Ferrous Materials

The polished rake face of the new inserts is said to improve chip removal, and the extremely sharp cutting edge creates a softer cutting action. The softer cutting action enables machining of unstable components and components with long overhangs.

Walter Introduces New Milling Grade That Finishes With One Cutting Edge

Walter’s new WHH15X milling grade can reportedly provide extra-long tool life, especially with hardness of 58 HRC or greater. The new grade can be used universally for finishing on ISO materials P, K and H, and is said to be ideal for copy milling in die and mold making.

Walter USA Set to Acquire GWS Tool Group

The partnership will increase Walter’s and GWS’ position in the manufacturing of advanced components and light-weight materials. In addition, GWS’ products will expand the overall offering for Walter in North America.

Walter Releases Highly Stable Cutting Tool

Walter’s Xtra·tec XT M5009 is said to maximize feeds, tool life and productivity, as well as boost process reliability while also reducing cutting tool material costs. The cutter’s high level of stability makes it ideal for minimal material removal and variable conditions.

Walter Unveils Round Insert Milling Cutter

According to Walter, the new Xtra·Tec XT M5468 is suitable for steel, stainless steel, cast iron, non-ferrous material with difficult cutting properties and hard machining. The company claims it is ideal for copy milling with minimal material removal.

Walter's Thread Formers Reduce Torque, Improve Lubrication

Walter’s TC420 Supreme thread features a radial internal coolant for blind-hole and through-hole threads, which the company claims is optimized for maximum performance in universal applications.

New Walter Copy Turn System Offers Stability

Walter released the W-1011-P/WL25 Copy Turn system, with positive locking technology for enhanced stability, longer tool life and reduced vibrations, according to the company.

Walter Cermet Turning Inserts Boost Stability

Walter’s indexable cermet turning inserts use the company’s FP2 geometry to reduce vibration, produce stronger corners and enhance surface finish.

Walter Increases Strength and Teeth of Xtra-Tec XT M5130

Walter has revised its Xtra-Tec XT M5130 shoulder milling cutter, increasing its productivity with more teeth, an enhanced clearance angle and a new insert-mounting position.

Walter's AC001 and A3000 Introduce Preset Vibration Damping

Walter’s AC001 vibration damping adaptor for long milling tools and A3000 boring bar line include preset axially and radially flexible damper elements to enhance stability for machining deep cavities.

Walter Xtra-tec XT M5012 Comes Fully Ground or Sintered

Walter’s Xtra-tec XT M5012 ships in fully ground and sintered configurations, increasing the cost-effectiveness and precision of this versatile face mill.

Walter M5137 Xtra-tec XT Cutter Reduces Finishing Operations

Walter’s M5137 Xtra-tec XT shoulder milling cutter features 90-degree approach angles, which it says reduces the need for additional finishing operations.

Walter Increases Tool Life With ISO-H and ISO-S CBN Grades

Walter WBH20 and WBS10 grades provide improved quality, reliability and tool life in grooving operations on ISO-H and ISO-S materials, respectively.

Walter M2471 Milling Cutter Reduces Cutting Tools Costs

The Water M2471 milling cutter features a new, double-sided indexable round insert that can reduce cutting material costs by up to 20 percent.

New Walter CBN Grades Optimized for Challenging Materials

Walter’s new WBK20 and WBK30 CBN grades have edge-preparation designs that are optimized for applications in cast iron and hardened steel.

Walter's Xtreme Evo DC160 Advance Provides High Productivity

Walter USA’s Xtreme Evo DC160 Advance solid carbide drill is designed for high productivity drilling in a wide range of materials.

Walter USA's Accure-tec A3000 Boring Bar Features Vibration Damping

Walter USA’s Accure-tec A3000, with its vibration damping system, is designed to excel beyond 6 × Dc.

Walter USA's G3051-P Arranges Inserts for Efficient Grooving Along Shoulders

Walter USA’s G3051-P grooving system, designed for grooving along shoulders, uses MX22-2L/R indexable inserts inclined by 3 degrees in the insert pocket.

Walter USA's MU5 Insert Benefits Low-Volume, High-Mix Turning Applications

The MU5 double-sided indexable insert from Walter USA can be used for turning steel forged parts as well as stainless materials.

Walter USA's MC232 Perform Milling Cutter Increases Edge Stability

Walter USA’s MC232 Perform series of solid carbide milling cutters feature a corner radius and reduced neck.

Walter Acquires Melin Tool Co.

Michael Wochna will remain president of the Cleveland, Ohio, company.

Walter USA Adds PCD Inserts to Its Cut GX Grooving Series

Walter USA has added polycristalline diamond (PCD) grooving inserts to its Walter Cut GX grooving system.

Walter's M4791 Routing Cutter Can Be Used on Lathes and Machining Centers

Walter USA has expanded its M4000 milling cutter line with the M4791, a routing cutter capable of plunging in solid material and producing a true flat bottom.

Walter USA's DC160 X-treme Evo Advance Enables Precision Drilling

The DC160 X-treme Evo Advance solid carbide universal drill from Walter USA is designed for high positioning accuracy with a thinner web at the point and advanced positioning of the margins for hole guidance.

Walter's CBN Grades Provide High-Quality Surface Finish

Walter’s WBH10C, WBH10 and WBH20 CBN grades are designed for improved turning of hardened steel ranging to 65 HRC.

Walter's D4120 Drill Speeds Chip Removal

Walter USA’s D4120 is an indexable insert drill from the P484 family that is designed for wear-resistance and longer tool life.

Walter USA's TC117, TC217 Advance Cut Taps Provide High Threading Productivity

Walter’s TC117/TC217 Advance cut taps provide high threading productivity in a wide range of materials.

Walter USA's WKV10, WKV20 Insert Grades Benefit Cast Iron Turning

Walter USA’s WKV10 and WKV20 insert grades for the Perform line of turning tools are marketed as versatile and cost-effective for small- and medium-batch applications in cast iron (ISO K).

Walter USA Now Offers Custom Indexable Inserts Through Its Xpress Service

Walter USA has added indexable inserts to the range of products available via the Walter Xpress fast delivery service.

Walter AG Appoints New President

Richard Harris has held various management positions with Sandvik, the parent company to Walter AG, since 2002.

Walter USA's D3120 Drill Provides Stability with Reliable Chip Removal

Built to provide trouble-free drilling in virtually all conditions, Walter USA’s D3120 indexable-insert drill features square positive inserts with four cutting edges, reducing cost per edge.

Walter USA's WMP45G Grade Is Designed for Cutting Turbine Blades

The grade is available in round indexable inserts for the F2334R copy milling cutter for face milling and copy milling of martensitic and austenitic stainless steels.

Walter AG Appoints President of Americas Sales Region

Richard Garrick will oversee Walter USA, Walter Mexico, Walter Canada and Walter Brazil.

Solid Carbide Drill Provides 140-Degree Point Angle for Accuracy

Walter USA’s DC150 Perform 5×Dc is designed to be a versatile and cost-effective solid carbide drill that can be used with all materials and with a broad range of workpieces.

Grooving Inserts, Holders Elevate Productivity, Tool Life

Walter USA has released Walter Cut MX grooving inserts.

Drill Designed for Versatility at an Economical Price Point

The DA110 Perform drill from Walter USA can be used universally and cost-effectively for a range of materials, the company says.

Modular Helical Cutter Promotes Process Reliability in Unstable Conditions

The M4258 modular helical milling cutter from Walter USA promotes cost efficiency and process reliability in slot milling and can be used for ramping, pocket milling, shoulder milling and circular interpolation.

Walter USA Tool Catalog Now in MachiningCloud

Walter USA customers are expected to be able to increase productivity and achieve greater accuracy by more easily downloading tool information directly into their CAM, simulation and tool management systems.

Indexable-Insert Drill's Polished Surfaces Resist Wear

Walter USA has introduced the D4140 indexable-insert drill, a tough and versatile new drill designed to deliver maximum process reliability and extended tool life.

Thread Mills Combine Pros of Thread Milling, Tapping

Walter USA’s range of T2711/T2712 thread milling cutters for large threads has been expanded with three new inserts and two tool bodies for cutting M56 and M64 threads.

Taps Combine Performance in Steel with Process Reliability

Walter USA LLC’s TC120, TC121 and TC122 Supreme blind hole taps combine improved performance in steel with increased tool life and process reliability, according to the company.

Ceramic Milling Cutters Increase Productivity, Cutting Speeds

Walter’s MC275/MC075 Walter Prototyp ceramic milling cutters increase productivity, cutting speeds and metal removal rates in the machining of nickel-based alloys.

Solid Carbide Micro Drill Meets DIN 1899 Standards

Walter USA has released the DB130 Advance, its smallest solid carbide micro drill

Inserts in Expanded Line Promote Long Tool Life

Walter has announced several extensions to its Tiger-tec Gold inserts.

Ceramic Cutting Grade Enables Roughing Cast Iron at High Speed

The WCK10 ceramic cutting grade from Walter is designed for roughing gray cast iron at high cutting speeds

Solid Carbide Milling Cutters for Hard Machining

Walter has introduced its ISO H Advance line of solid carbide milling cutters.

Turning Inserts for Machines with Limited Cutting Parameters

Walter USA has introduced two insert grades in its Perform Line of turning tools, the WPV10 and WPV20.

Dynamic Milling Cutter Insures Even Wear

The MD133 Supreme milling cutter from Walter USA is designed for dynamic milling and delivers process reliability, particularly during unmanned operation.

Grooving Boring Bar’s Coolant Holes Optimize Blind Bore Machining

Walter USA’s Walter Cut G1221-P grooving boring bar with precision cooling is designed for recessing and internal grooving.

Grooving, Parting Inserts Ensure Reliable Handling

The Walter Cut MX grooving and parting tool is said to improve accuracy, stability and process reliability.

Manufacturing News of Note: December 2017

SW North America opens a new facility to strengthen its automotive presence, Walter and Starrag focus on aviation and power turbines, and other manufacturing news.

Grades’ Coating Reduces Friction in Grooving, Parting

Walter has introduced three new Walter Cut GX Tiger-tec Silver CVD grooving and parting grades (WKP13S, WKP23S and WKP33S) for use on steel and cast iron applications.

Walter, Starrag Host Fifth Annual Turbine Technology Days

The companies claim that the aviation industry’s boom and the power generation industry’s increasing need for gas turbines comprise the turbine manufacturing industry’s call to action.

Insert Geometry Designed for Targeted Cooling

Walter's FM5 finishing and RM5 roughing indexable insert geometries are designed to deliver optimal cooling, longer tool life, and increased productivity in high-temperature alloy and stainless-steel machining.

Walter USA Appoints U.S. Managing Director

Dan Shelton previously worked with Sandvik Hyperion and Sandvik Machining Solutions.

Wiper Inserts Expand Milling Cutter Capabilities

Walter has expanded the capabilities of its Walter Blaxx M3024 heptagonal milling cutter with new wiper inserts.

Cost-Effective Milling Cutters Universally Applicable

Walter has added to its range of solid carbide milling cutters with the introduction of its MC232 Perform product line.

Geometry/Grade Combo Makes Burr-Free Parts

Walter USA introduces the MS3 cutting geometry with the new WSM01 grade.

Walter USA Appoints Business Development Director for North America

Thomas Benjamin will be responsible for analyzing markets and handling relationships with business partners in the region.

Walter, Comara Announce Joint Venture

The venture is intended to expand the partners’ smart manufacturing product offerings.

Custom Cutters Quicker

An online quoting service is said to speed and simplify quoting and purchasing of custom cutting tools.

Grooving Tool Stably Performs Radial, Axial Grooving Operations

Walter USA’s Walter Cut G1511-P grooving tool with precision coolant supply is available in 1.0" shank sizes and is designed to provide increased tool life and productivity.

Drilling Grade for Cast Iron Counteracts High Operating Temperatures

Cast iron drilling has taken a significant step forward with an expanded insert range for new diameters in the high-speed Color Select P6005-WKK45C grade for Xtra-tec B401x point drills.

Ramping Cutter Promotes Process Reliability Even at High Speeds

The M2131 Sky-tec ramping cutter from Walter USA brings improved process reliability to the machining of nonferrous metals such as the aluminum-wrought alloys or aluminum-lithium alloys often used in aircraft structural components.

Walter USA Appoints Marketing Director for Americas, UK

Kurt Ludeking has been with Walter since 2010.

Double-Sided Inserts for Rough Turning Applications

Walter has introduced double-sided ISO indexable inserts with RP7 geometry, providing maximum process reliability in rough turning by combining a ground contact surface with an optimized profile that has a tailored protective chamfer to guard against fracturing.

Insert System Reduces Tool, Storage Costs

Walter’s M4000 program uses an insert system that has a single, basic-shape compatibility with every M4000 body.

Mobile App Helps Users Identify, Correct for Tool Wear

Walter USA’s wear optimization app, which works on all current mobile devices and operating systems, enables users to identify specific forms of wear on indexable-insert and round-tool solid carbide applications, from milling, drilling and threading to turning, grooving and parting.

Boring Cartridge Increases Metal Removal Rates

Walter has broadened its line of boring tools with the introduction of the B3220 boring cartridge for axial-radial offset roughing (ARS), expanding on previous methods that were either symmetrical or asymmetrical.

Drill Insert’s Geometry Improves Performance in Cast Materials

Walter’s P6005-WKK45C point drill insert is designed for performance and cost-effective drilling of ISO K cast materials.

Blind-Hole Taps Handle Stainless Steel Applications

TC142 blind-hole taps from Walter USA are designed for machining stainless steels and ISO-M materials.

Octagonal Face Mills Achieve Quality Surface Finish on Cast Iron

Walter USA’s M2025 and M2026 octagonal finishing face mills are designed to deliver high surface quality on large cast iron components.

Orbital Thread Mills Promote Process Reliability

Walter USA’s Unified National Fine (UNF) orbital thread mills are available in 2×D and 3×D models with large shank diameters promoting vibration-free machining, even with a long clamping length.

Walter USA Redesigns Web Platform for Mobile Devices

The site now uses responsive design, accommodating viewing and ordering using a smartphone or tablet as well as a PC.

Blind-Hole, Through-Hole Taps Handle Range of Materials

Walter USA’s high-performance Prototyp TC115 and TC216 taps are designed to make blind-hole and through-hole threads, respectively.

Indexable Insert Grade Designed for Productive Steel Machining

The Tiger-Tec Silver WPP05S insert grade is a wear-resistant, indexable grade from Walter USA said to deliver high performance and productivity in steel machining, particularly for roughing forged components and long production runs.

Taps Boost Performance, Reduce Costs

Walter USA offers a pair of versatile, high performance and cost-effective taps: the Walter Prototyp TC115, designed for blind-hole threads, and the TC216 for through-hole threads.

Drill Line Adds Clamping System, Indexable Inserts

Walter USA has expanded its family of Xtra-Tec insert drills with the addition of the Walter Capto clamping system and indexable inserts with Tiger-Tec Silver cutting tool material.

Modular Boring Tool Delivers Flexibility

Walter USA’s B3230 Walter Capto fine boring tool is suitable for standard as well as reverse machining and features internal coolant supply up to the cutting edge.

Lightweight Boring Tool Eases Tool Changes

The PrecisionMedium B4031.C Light Weight Solution (LWS) boring tool from Walter USA is equipped with the company’s Capto modular toolholding interface to ease handling, speed tool changes and enhance precision.

Deep-Hole Drills Avoid Pecking

Walter USA has added the Titex X-treme D40 and D50 to its line of solid carbide deep-hole drills.

Through-Coolant Capability Reduces Cycle Time

Aided by Walter Titex tooling and a new higher-rpm machine tool from Fryer, Toolmasters Inc. was able to cut cycle time on a complex die set.

Cutter Promotes Chip Removal during Deep Plunging

Walter USA has expanded its Proto-max series of high-performance solid carbide end mills with the Prototyp Proto-max "Tough Guys" (TG) end mills, designed for use with steel, stainless steel, cast iron and super alloys.

Micro-Drills Feature Internal Cooling

Walter USA has expanded its Titex X-treme DM micro-drilling line with tools in the 16×D and 30×D drilling depth ranges.

Inserts Boost Productivity in Cast Iron

Walter USA’s Tiger-tec Silver line of high-performance insert now includes the RK 5 and RK7 geometries designed to enhance cutting speed, reliability and tool life in ISO K (cast iron) materials.

Walter USA Announces Channel Development Team

The team will focus on the company’s sales channels, partners and overall sales force.

Inserts Ease Difficult Turning Applications

Walter USA offers a series of insert geometries designed to improve productivity in difficult turning applications.

Tool Selection System Available

Walter USA offers its Walter Global Productivity System (Walter GPS), a web-based tool selection system.

Tap Improves Thread Quality

The Walter Prototyp Paradure short-chip blind-hole tap from Walter USA is designed to increase process reliability and quality when tapping long-chipping, high-tensile-strength steels.

Inserts for Steel Turning Applications

Walter’s Tiger-tec Silver turning inserts are designed to reduce machining times and increase process reliability, particularly in steel turning applications, the company says.

Ceramic Grades for Super Alloy Turning Operations

The WIX10 and WWS20 complementary ceramic grades from Walter are designed for turning high-temperature super alloys such as Inconel, Waspaloy, Stellite and other heat-resistant materials that can create create greater stresses and increased wear in carbide tools.

Insert Geometries Designed for Turning

Walter USA has added four cutting tool insert geometries to its Tiger-tec Silver for turning family.

Walter USA Opens New Technology Center

A new 40,000-square-foot technology center complements the company’s efforts to be a competency leader in the cutting tool industry.

Walter to Expand North American HQ

Cutting tool manufacturer Walter USA has announced plans to build a new North American Technology Center at its headquarters in Waukesha, Wisconsin. Featuring demonstration and application trial areas, the 40,000-square-foot facility will be designed to help educate customers, channel partners and employees on the company’s products.

New President at Walter

Milko Merlo has become president of cutting tool supplier Walter AG, parent company of Walter USA (Waukesha, Wisconsin). He succeeds former president Andreas Evertz, who will become president of Sandvik Machining Solutions, of which Walter is a part. Most recently, Mr.

Solid Carbide Drills Available in Non-Coolant-Through Versions

Walter USA has expanded its line of Walter Titex X-treme high-performance solid carbide drills to include non-coolant-through versions, designed to cover the same application areas and provide increased performance and tool life.

Milling Grade Designed for Faster Metal Removal

The Tiger-tec Silver WKP25S indexable milling grade from Walter is designed to maximize productivity by enabling increased feed and cutting speeds, and increased rates of metal removal, particularly in the machining of steel and castings.

Making Music while Making Chips

Machinists are creative people. So why should it surprise us that they are musically inclined?

Drill Reaches 70×D Drilling Depth

Walter Titex’s XD70 drill is designed to reach a drilling depth of 70×D without pecking, exceeding standard depths of 30×D.

See The Tool's Value Instead Of Its Cost

This company is embracing high-performance tooling on its turning centers. The "sticker shock" is no reason not to do this. In one case, though, the shop found a way to limit the cost of the tool and increase productivity at the same time.

Thread Milling On A Tiny Scale

Machining internal threads in difficult materials is challenging, especially when hole diameters are small. Thread milling offers advantages for these applications that are important to consider.

Insert Provides Long Life, Short Cycle Times

Novatek, a manufacturer of diamond products used in the oil and gas, mining, construction and other industries, needed to reduce both costs and production time on a job involving very large workpieces. The Tiger-Tec black and gold WPP10 insert from Walter USA, which features an aluminum oxide coating designed to prolong tool life at high surface footages, helped the company increase feeds and speeds and create smaller, more manageable chips.

Modular Design Enables Precision Boring Over Large Diameter Range

The B4035 boring head features an optoelectronic adjustment measuring system and digital display with 0.0001" accuracy in the diameter range of 0.118" to 4.882" (3 to 124 mm). Maintenance-free automatic balance compensation and flexible screw fit connections make this tool suitable for virtually all spindle adaptat

Cutting Tool Manufacturer Helps Growing Shop Improve Efficiency

While nearly always desirable, growth can bring its own set of challenges. A case in point is Tri-K Machining, a shop that is seemingly on the fast track to success. Business has increased by more than 300 percent during the past 12 months. However, management soon realized that keeping up with this added work

Reducing Production Costs Keeps Processes In-House

When the Fendt Component production department identified the need to reduce the production costs associated with the development of transmission housings by 50 percent, it realized that failure to meet this target would require outsourcing, resulting in the loss of a considerable number of jobs. A team consisting of a tool manufacturer, a machine supplier and component production specialists met this challenge, with tooling playing an instrumental role.

Facilitating Faster Speeds And Shorter Cycle Times With Cutter Implementation

“Perfection is a goal every business strives for, but when it’s part of your name, you feel even more responsible for it,” says Scott Gauerke, owner/president of Perfect Patterns, an Appleton, Wisconsin-based manufacturer of patterns and permanent molds for a number of industries, including automotive, light commercial and agricultural.

Drill Reduces Machining Time, Increasing Capacity

This company specializes in developing electromagnetic systems with switching and/or sensor capabilities. Typical product applications include general mechanical engineering and plant construction; automotive engineering equipment and materials handling equipment; and automation, medical and power technologies.

Competitive Testing Process Helps Manufacturer Take The Bite Out Of Cycle Times

To find a line of indexable inserts that would improve cycle times and provide increased tool life, this company invited eight tool manufacturers to test their inserts on turning applications on ductile iron workpieces machined at the company's facility.

Tools For Milling In Z

The fastest way to mill away a lot of material may be to attack it head on with a move in the Z direction.