Watchmaking: A Machinist’s View

Old-world craftsmanship combines with precision machining on a vertical machining center and Swiss-type lathe to produce some of the only U.S.-made mechanical wristwatch movements.

#micromachining

Hunched over his desk and peering through an eyepiece, Cameron Weiss pays little attention to the machine tools in the next room. The Swiss-trained master watchmaker is usually far too busy polishing, burnishing, fit-checking and assembling the hundreds of pins, gears, springs and levers that go into the mechanical “movements” powering each luxury timepiece.

That’s not to suggest Mr. Weiss doesn’t appreciate the critical role these machine tools play in realizing his dream: to build his own brand of wristwatches, one based unapologetically on his own artistic ideals. Just as emblazoning his family name across the face implies a certain aesthetic, the label “Los Angeles, California” implies a deep-seated desire to restore prestige to a domestic industry that largely collapsed with the advent of cheaper, more accurate quartz movements in the 1960s. For Mr. Weiss, restoring that prestige means not just assembling the parts here, but making them here, too.

Featured Content

That’s why Weiss Watch Co. needs machine tools. For all the founder’s skill, leveraging centuries-old techniques to handcraft parts like the brass main plates for movements, the bridges that hold those movements in place, and the outer casings would be prohibitively expensive and time-consuming. It would also be anathema to the goal of not just making art, but making that art accessible. Without flexible, modern machining technology, it wouldn’t be possible to iterate multiple prototypes before finalizing and producing a design in quantities that have so far ranged between 5 and 500 per series, Mr. Weiss says.

The three-axis VMC and Swiss-type lathe performing this work are housed in a garage adjoining the company’s 2,100-square-foot office park space in Torrance. The machines’ sole programmer and operator is Grant Hughson, a former applications engineer for cutting tool manufacturer Sandvik Coromant and Mr. Weiss’s business partner in a separate entity: Pinion Precision Technology. The partners’ goal for Pinion Precision is ambitious: to produce parts for timepieces beyond the Weiss brand. Specifically, they hope to take advantage of the anticipated gap left by Swatch, a prominent parts supplier in Switzerland that is abandoning this business to focus solely on making complete watches.

There’s good reason for confidence in Pinion Precision’s ability to capture this work, Mr. Weiss says. One lesson of the early days of Weiss Watch Co., when he was still assembling movements at his kitchen table from almost all Swiss components, is that other machine shops generally aren’t used to making artwork. “Every part we make not only has to fall within a very tight tolerance; it also has to be visually appealing,” he says.

In the past, he continues, shops confidently accepted the kind of work that Mr. Hughson is now doing in house, only to struggle to do that work cost-effectively. This includes some companies already accustomed to small parts (most pinions measure less than 1 mm), high precision (+0.0002/-0 inch for some hole-pinion intersections) and smooth surface finishes (16 RA or smoother are typical). In fact, he recalls one instance when a potential supplier was so humiliated by unexpectedly lengthy turnaround time on a prototype order that it offered the parts for free.

Mr. Hughson adds that the difficulty of this work goes beyond meeting stringent specifications. After all, one might say machinists are born for such challenges. What can be more difficult is adhering to quality standards that might seem subjective. Likewise for performing operations in unconventional, counterintuitive ways in order to support painstaking hand-finishing processes.

Parts as Art

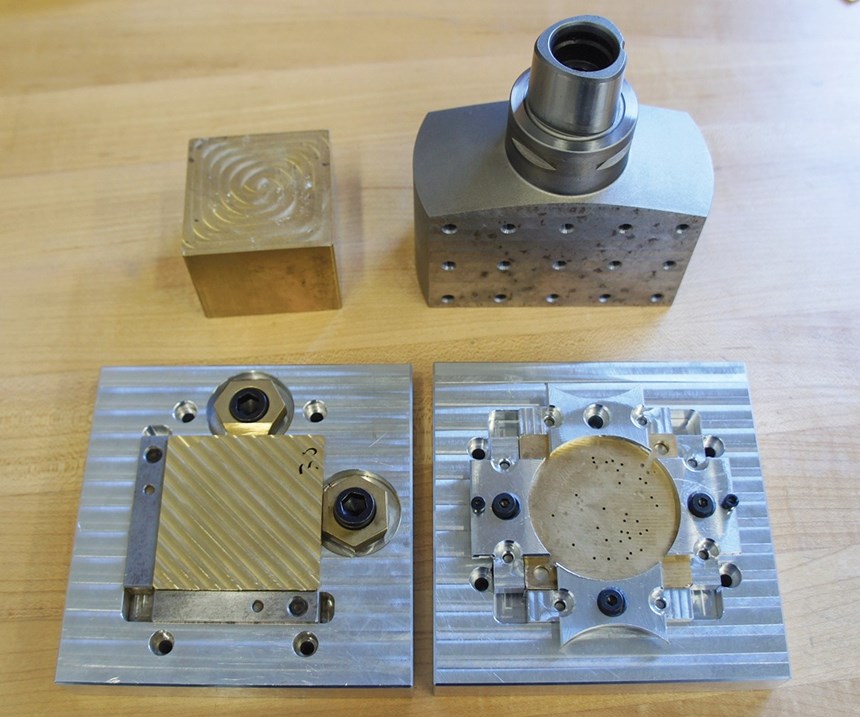

Few machine shops paint with their tool paths, but work from Weiss Watch Co. demands it. On brass bridge components like the ones pictured in the slideshow above, attention must be paid to every swirl and line, and standard tool paths often don’t cut it, whatever the measured tolerance or surface finish. “For all the finishing strategies, for the most part, the geometry is actually being drawn,” Mr. Hughson says. “The tool path has to go a certain way—you can’t just click an area and say, ‘pocket this.’”

He cites the Geneva striping patterns as a particularly good example of how aesthetics can make outsourcing machining difficult. Visible in the opening photo of the slideshow above, these broad, diagonal bands stretching across the main plate and bridge derive much of their visual appeal from parallel internal tool marks that arc toward the intersection with an adjacent stripe but never jump the gap. The lines within are shaped a certain way for both visual appeal and to catch dust inside the movement, and maintaining a clear border between each stripe is essential, Mr. Hughson says. Cutting these features on a mill rather than a dedicated Geneva striping machine requires what he says is an unconventional approach to programming. For instance, rather than using a constant stepover on the shop’s FANUC Robodrill VMC, he employs a full-width slotting cut, then overlaps half of that cut with another full-width slotting path.

From there, no specific measurement or series of measurements can definitively determine whether the striping is correct. It’s a purely visual standard, with Mr. Weiss using a microscope to evaluate the machined pattern against a chosen ideal. What’s more, width and spacing of the bands can differ slightly from movement to movement and from prototype to prototype during the development of a new movement. Certain part features must also be cut from certain portions of the brass square that measures 2 by 2 by 0.125 inches to ensure consistent striping once the movement is assembled. Further complicating things, features spaced too close together don’t leave enough space for cutting tools, while those spaced too close to the edge of the stock run up against unsightly tool entry and exit marks.

Ensuring tool access to the various main plate and bridge features is also important for chamfering edges to prevent burr formation. Mr. Weiss prefers to deburr by hand in some cases, but many parts are too small and fragile. Mr. Hughson says he spends a lot of time strategizing about how to leave a clean surface or to ensure burrs form in a manner that doesn’t disrupt the handwork. For instance, a certain feature might be machined from the opposite side of the part than initially intended, or a profile cut might not fully penetrate the part in order to prevent a burr from pushing through to the other side.

None of this is to suggest that reliable, repeatable machining processes are impossible to develop for watch components, Mr. Hughson says. Yet, capacity for doing so is limited with two machine tools and a single programmer/operator (the rest of the team consists of Mr. Weiss’s wife, Whitney, who handles marketing; as well as Lisa Odland, Mr. Weiss’s watchmaking apprentice, and a front office administrator Christy Broderson). Meanwhile, the complexity of the work can be a tall order for outside shops that aren’t dedicated to it. Scaling production is the goal, but the art simply can’t be compromised.

Making Time

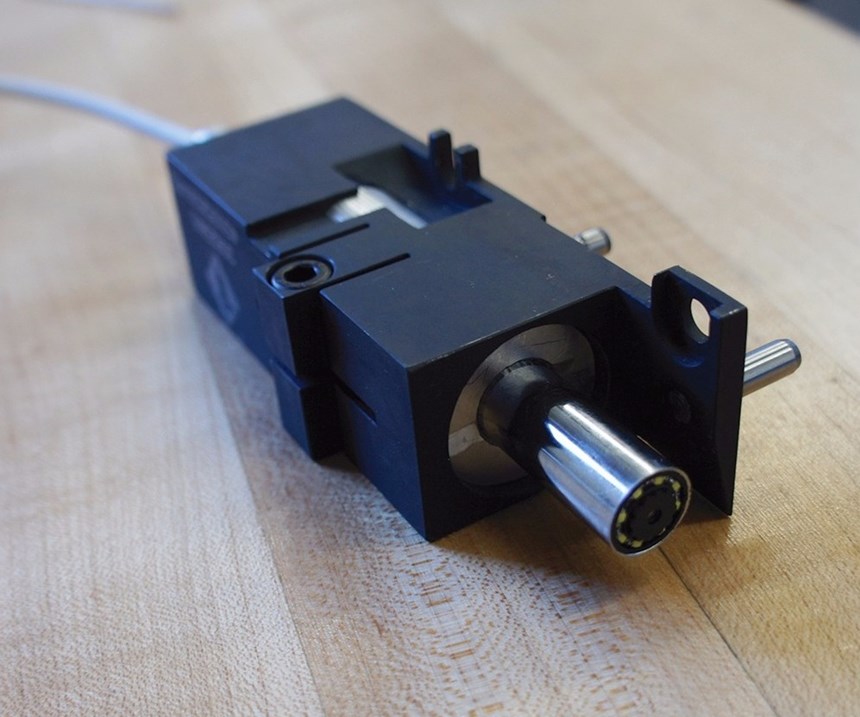

Given the realities of outsourcing, Mr. Hughson handles the lion’s share of machining process development. Larger parts go to the Robodrill, sourced from Methods Machine Tools. The smallest, most complex components usually go to what he calls a “decked-out” Swiss-type lathe: a nine-axis Tornos Swiss Nano imported from Switzerland with a number of nonstandard features that are well-suited for watchmaking. For instance, two individually controlled, high-frequency milling spindles offer 60,000 and 80,000 rpm respectively—sufficient speeds for effective milling with even the smallest cutting tools. Among other features, the gang-tooled machine also offers capability to synchronize workholding and milling spindles for gear hobbing operations, as well as a tube system with a vacuum for removing the tiny parts.

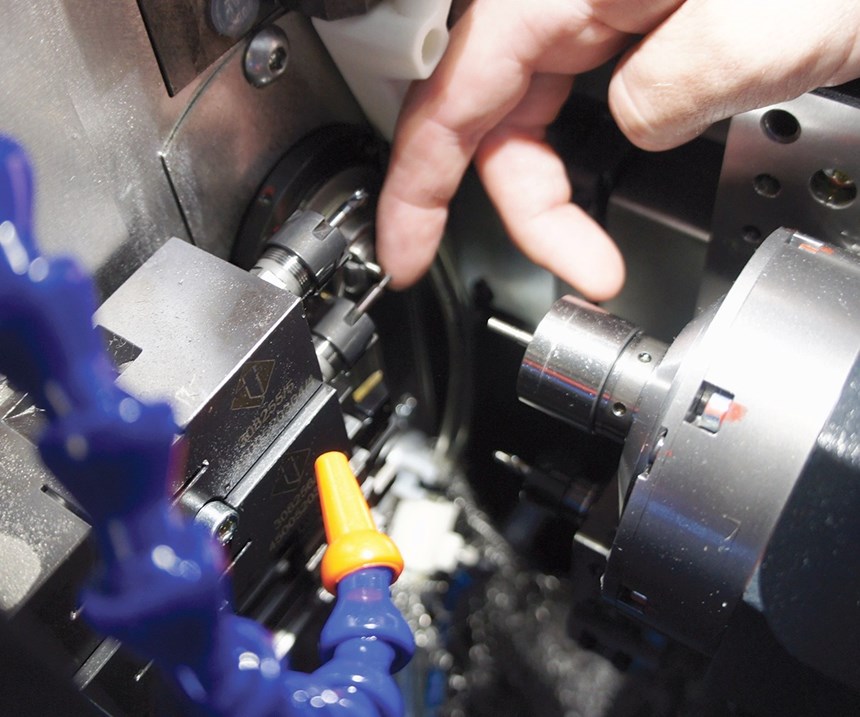

Still, iterating prototypes as quickly as possible demands not just the right technology, but also homegrown ingenuity. On the Tornos, for instance, even capability to effectively run tools like an 0.03-inch slitting saw goes only so far when the setup needs to change. “You can’t even stick your fist between the main and subspindle,” Mr. Hughson says, explaining that it can sometimes be difficult to see whether a tiny feature has actually been machined or even whether a part has actually transferred for subspindle backworking operations. What’s more, a single part might require operations with as many as 10 different cutting tools, each with its own offset, and with offsets for the same tool differing depending on its approach vector. Setting these offsets by touching off each tool against a sheet of contact paper—a critical step to avoid damaging not just fragile, expensive parts, but also fragile, expensive tools—can be a time-consuming proposition.

That’s why Mr. Hughson decided early on that he’d have none of it. Instead, he sets offsets visually, guided by a crystal-clear image of the workzone on a flatscreen LCD that’s detailed enough to view individual chips stuck to workpieces that only barely protrude from the main spindle guide bushing or subspindle micro chuck. This image is generated by a tiny microscope camera installed into a toolholder on the gang slide. “I set up all the tools, call up the stock offset for each one, check it out, and adjust as necessary. There’s no need to touch off anything,” he says. This homegrown system also provides peace of mind that programs are solid and that everything has been set up and machined correctly.

On the VMC, workholding has been the focus of the most significant strides toward speeding prototype iteration. Specifically, Mr. Hughson prefers to focus on ensuring an accurate, repeatable interface between fixture and machine rather than putting too much effort into the interface between part and fixture, as his original designs did with their precision locating pins. After all, prototyping often requires taking parts off the machine for examination. As long as the fixture location doesn’t vary more than a few thousandths of an inch from its original position, on-machine probing can quickly and automatically update the work offset around the part.

As a former Sandvik employee, he naturally turned to modifying Capto quick-change tooling blanks to provide the critical interface between machine and prototype workholding. Compared to relying solely on a repeatable fit, this strategy makes it easier to ensure features on opposite part sides are located correctly in relation to one another. Fixture designs can be more forgiving, the repercussions of workholding wear or damage are less severe, and problems are easier to troubleshoot.

Ticking Ahead

The company’s first movement to be constructed almost entirely of U.S. parts is the CAL 1003 that powers the American Issue Field Watch. This gold-plated first version was limited to just 50 pieces. Now, the movement is on its fourth production iteration, which features a higher beat rate than previous versions as well as a “hacking” mechanism that enables users of the $1,995 watch to start and stop it at will. Moving forward, the goal is to bring production of the last few components still produced in Switzerland—hairsprings and jewels—onto U.S. soil. Although the capability is here, Mr. Weiss says suppliers require the opportunity to produce at certain volumes before they’d even consider the work. He and Mr. Hughson alike expect scaling up from here to be an incremental process, as it’s been from the beginning. “We’re learning as we go along,” Mr. Hughson says.

That may be so, but the company has come a long way in four short years. It’s done so by following essentially the same model that spawned the reputation for U.S. watchmaking it aims to restore. Beginning in the mid-19th century, U.S. companies like Waltham Watch Co. supplemented the technique of the Swiss masters with production equipment that made watches cheaper and easier to make without compromising the craft, Mr. Weiss explains. The industry declined with the advent of quartz movements, but the Swiss managed to maintain their mechanical traditions, with the continuing success of brands like Rolex driven largely by enthusiasts who appreciate the engineering that goes into hand-assembled timepieces with hundreds of parts. By leveraging a similar strategy as Waltham—the merger of old-world craftsmanship with modern manufacturing technology and technique—Weiss Watch Co. aims to attract a similar clientele, albeit one with a particular appreciation for a “made in America” label.

So says the watchmaker. As for the machinist, Mr. Hughson couldn’t be happier doing work that regularly challenges conventional approaches to machining parts. And novelty isn’t his only source of motivation these days. “In much of high-end manufacturing, it’s almost like you have a hidden double life because you can’t show it off,” he says. “In watchmaking, I can say, ‘Look at this little machine on my wrist: This is what I do!’ For me, that’s been a huge thing: making something beautiful for its own sake.”

RELATED CONTENT

-

Effective Plastic Machining Requires Effective Chip Control

Clean, burr-free cutting is fundamental to competitiveness for a shop that specializes in micro-machining complex geometry from some of the softest materials in the industry.

-

What Should You Consider When Turning Micro Parts on a Lathe?

Various factors, including the machine, cutting tools and operator, must be taken into consideration to turn very small parts.

-

Does Small-Hole Drilling Demand a Fast Spindle?

A reader with a 10,000-rpm drill press can drill a 0.019-inch hole in stainless, as long as all the contributors to runout are controlled.

.1692800306885.png)

.1687801407690.png)