You receive a call from your parts supplier stating that a new general manager has audited his company’s job quoting data going back several years. The audit, your supplier says, has revealed you have been undercharged, quite significantly, for the manufacture of your parts. You are told that if you want to retain the company as your supplier, you will have to renegotiate your contract and pay a higher premium for your parts going forward.

Now consider the reverse scenario.

Featured Content

You own a mid-sized job shop that specializes in precision-machined parts. For years your company has been pushing the production needle into the red, maintaining as many customers as it can. You recently hired an experienced general manager who immediately detects two problems: Your company is taking on too many small orders and, more to the point, too many customers. Many of your customers’ orders are limited to one to 10 parts, and the sheer volume of unique setups these parts require are killing your spindle utilization rates, eating into profits and hurting employee morale.

A sample block of raw aluminum that Duo CNC machined into parts used at entertainment parks.

This second scenario is one that recently faced Duo CNC Machining, a mid-sized job shop located in Langley, British Columbia focused on precision machining for the energy, agriculture, clean-tech and packaging industries. For years, the company serviced up to 30 customers that rotated from month to month, forcing Duo CNC to adjust its raw material inventory according to how many customers had been added or dropped from the roster at any given time.

Duo CNC reacted to its new general manager’s audit with a solution that transformed not only the company’s core philosophy, but also helped increase revenue and profits by double-digit margins. But what company leaders might not have expected was the downstream effect of the policy they put in place: Namely, an improved company culture along with more time to implement technical improvements related to programming, fixturing and setups.

Culture Shock

When Terrance Visser acquired Duo CNC in 2016 as its new owner and CEO, he joined a company that had been working under high-pressure conditions for several years. Even without a machining background, Visser recognized that Duo was servicing too many customers who required low-volume production and short lead times —a recipe for stress, burnout and a company culture that had turned sour.

“The culture at Duo was a big focus for me at the beginning,” Visser says. “I can’t run a CNC machine, but I started doing what I could; cleaning the bathrooms every week, scrubbing machines and helping wherever I could. I worked hard to build a strong team culture. On-time quality parts is one thing, but we needed to address the relationship aspect of our work — not just among staff, but with our customers.”

One of the keys to achieving this arrived a year later when the company hired Helmut Hartmann, a German native and journeyman machinist, engineer and programmer with decades of experience working at machine shops in Europe and Canada. After being briefed on the company’s goals, Hartmann started digging into several years’ worth of Duo’s enterprise resource planning (ERP) software, ECI JobBoss, and specifically the company’s job cost reports.

Duo General Manager Helmut Hartmann and owner Terrance Visser discuss production on Duo CNC’s shop floor.

“I analyzed all of the different jobs we have here in-house, all the parts, and some of the pricing had never been updated,” Hartmann says. “In some cases, the original order volume was much higher than reorders. So we did an analysis and came to the conclusion that these jobs are not profitable for us.” Hartmann recommended shifting the company’s focus to higher-volume production along with, in his opinion, a long-overdue update on the company’s pricing. Focus on customers who can provide volumes of work that keep the machines running, he advised.

With leadership on board with this assessment, Visser and Hartmann set up meetings with some of the company’s existing customers. The two men had the unfortunate but necessary task of letting these customers know that Duo CNC had recalibrated its pricing. The reactions ranged from grudging acceptance to, “What? We can’t do this.”

“And we had to say, ‘Sorry, but we can’t do it the old way either,’” Hartmann says. Over the next several months in 2018 and 2019, through both attrition and through Visser’s push to focus on its long-standing vendor relationships, the company cut back its customer base from up to 30 down to a few core customers.

The result was that 2020 — a year marred by a global pandemic, no less — was a record year for the company. Duo CNC has increased its on-time delivery to 91% so far this year, as well as increased its sales volume by more than 50% — all while focusing on and improving several technical processes on the shop floor.

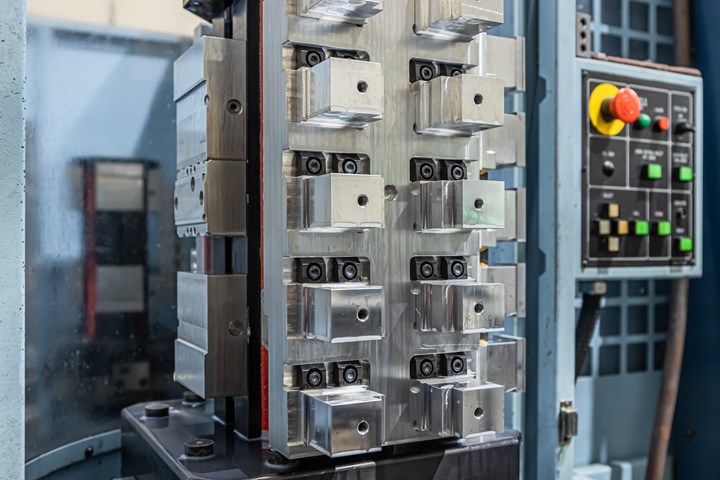

Duo CNC switched production of these 5052 aluminum parts to a Haas VF4 and Midaco pallet changer, immediately increasing spindle utilization with the ability to load additional pallets while the machine was running.

The Finest Moment

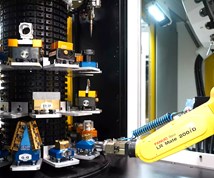

The first process that Hartmann tackled, alongside Duo CNC’s lead programmer, Zvezdomir Milev, was investing in new machining automation equipment, including a Haas VF4 and Midaco pallet changer. Both of these tools were immediately put to use on 5052 aluminum plates that the company had been machining two at a time. Hartmann and Milev decided to switch production of these parts to Haas VF4 and pallet changer, immediately increasing spindle utilization with the ability to load additional parts while the machine was running.

The switch also allowed milling and drilling operations to be performed on two pallets with the Haas rather than two machines that were manually loaded, a change that Hartmann estimates reduced overall cycle time by several minutes.

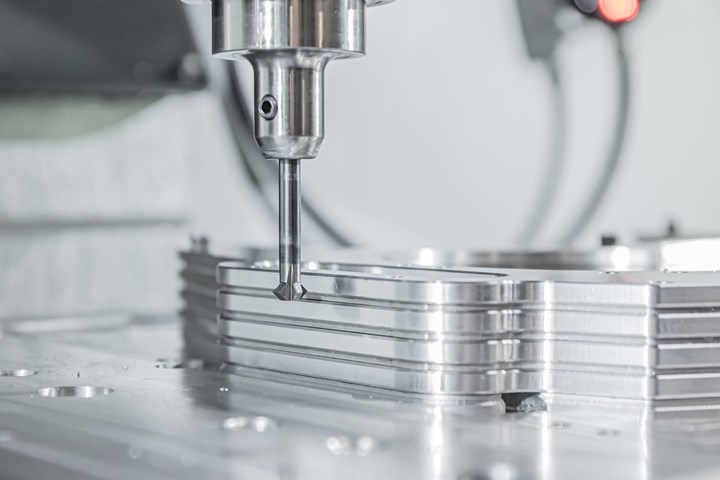

Decreasing Duo’s customer base allowed Milev to turn his attention to a family of large 6061 aluminum parts that, to his mind, were requiring unusually long cycle times. “Don’t machine air,” Milev says. “The chips have to fly, right? So I optimized and streamlined all of the programming cycles for this part where the cutter was feeding into the air.”

More importantly, Milev recommended the use of Mastercam’s dynamic milling with a solid carbide end mill rather than cutters with expensive inserts. The idea is to use as much of the flute length of an end mill as possible,” Milev says. In addition to increasing material removal rates by using long lengths of cuts, dynamic milling can be combined with climb milling (also known as down milling), in which the cutting motion of the tool is in the same direction as the feeding direction of the workpiece. “It all comes down to eliminating air cuts,” Milev says. “With dynamic milling, each move of the mill from left to right is removing material.”

Duo CNC began using dynamic milling to machine these parts, a change that Duo’s lead programmer says greatly improved throughput.

Milev says that, initially, the use of dynamic milling made some of his machinists nervous due to the much larger NC files that it generates. But, he says, two years after its implementation, they have become accustomed to it. “They see a bunch of X’s and Y’s and Z’s that don’t really show them where the cutter is going next or let them trace the motions of the end mill, but I tell them that they have to put their faith in modern technology. And now everyone knows that it’s a great way to remove material quickly at a low cost. And anything that’s fast and economical makes me happy.”

Duo CNC first utilized a Haas four-axis VMC to machine these tumbler blocks, a strategy that required the parts to be machined one at a time. But when the customer orders began to increase into the hundreds, change became necessary.

Finally comes what Milev refers to as one of Duo’s finest achievements since the company pared down its customer base and began focusing on process improvements. The part in question is a tumbler block from a customer that, at first, required very low quantities of the part. Hartmann and Milev first utilized a Haas four-axis VMC to machine the parts, a strategy that required machining the parts one at a time. But when the customer orders began to increase into the hundreds, change became necessary.

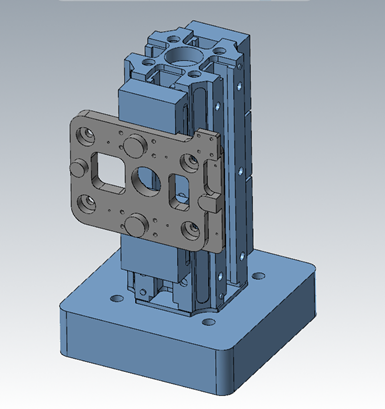

The company transferred the part to a Matsuura five-pallet HMC using two fixture plates attached to a tombstone that can machine 10 parts in op. 1 and 10 parts in op. 2.

Another view of the tombstone holding Duo CNC’s new setup featuring fixture plates and Mitee-Bite clamps.

The fixture plates are slotted for Mitee-Bite clamps that grip just 3 mm of extra stock on the workpiece, allowing the tool to access five sides of the part at once. Hartmann says that this strategy allowed the company to reduce the cycle time significantly for these parts.

Visser considers all of the changes that Duo CNC has implemented in recent years — focusing on its core customers and using time saved through automation to focus on process improvements and customer relationships — to be part of a broader philosophical change for the company. Gone are the days when Duo CNC will be used as an overflow job shop for companies. Prototyping is also off the table unless the company shows promise of developing into a production partner with Duo CNC.

“We realized that we're no longer a quote-unquote prototyping shop,” he says. “But it’s a different scenario when we find a customer that asks for prototyping with the intention to going into production, and that's exactly what happened with one recent customer. They are a large startup company that we helped with design, prototyping and programming, and now we stock their inventory. Is there a risk when you service only a few customers that the loss of their business would impact us? Of course. But in the same breath, there's a lot less risk in being able to manage these relationships that now go a lot deeper than they used to. Now when we look to add another customer, we're looking to grow right alongside them.”

RELATED CONTENT

-

Non-Traditional Methods For Making Small Holes

Consider these alternatives when conventional drilling can't do the job.

-

Which Five-Axis Machining Center is Right for You?

With so many choices in five-axis machining technology, how do you know which is best for your shop? First, consider the parts. Then, look at existing processes and potential five-axis benefits.

-

How One Job Shop Tackled Tungsten

When this aerospace job shop settled on machining tungsten alloys and other heavy metals as its specialty, it had to have a machine tool, cutting tools, workholding and process know-how to succeed.

.1692800306885.png)

.1687801407690.png)